| Nordair 737 CF-NAI and The Hose |

Bob

Bogash

|

|---|

| Home Safety Index Reader Comments Contact | |

The Hose

Frank Henley, one of Nordair's Exec's, could rightly be credited with introducing the Boeing 737 Twinjet into the commercial aviation scene in Canada. He was an early bush pilot that rose through the ranks. Back in the 1960s, Nordair had a route network that comprised two parts - a scheduled operation in southern Canada centered on Montreal and extending down into SW Ontario, but primarily supporting operations into the Canadian Far North, where cargo was King. The second part of their operation involved passenger charter flying - primarily Inclusive Tour charters - to Europe and to warm southern destinations in the U.S., Caribbean, and Mexico. The airplanes flew sked during the week and charter on weekends.  Frank Henley Frank Henley

Flying in the North was (and is) a challenge, -- besides the bad weather, lack of infrastructure etc - most all the airfields were unpaved gravel strips. There were several reasons the runways were (and are) gravel - money was certainly one factor. But environmental issues also play a role. The temperature extremes can play havoc with the pavement, causing frost heaves, etc. A gravel runway can be maintained fast and easily with nothing more than a road grader.

Nordair flew a piston engine fleet of 16 airplanes - 4 each DC-3, C-46, DC-4, and L-1049H Super Constellations. Piston engines don't like cold weather! So, transitioning from piston equipment to turbines involved a primary requirement of being able to operate off unpaved airstrips. Another was the ability to carry freight as well as passengers. Cargo was actually the mainstay of Arctic flying, which had begun back in the DEW-Line days. Turboprops were one possibility - but only the Lockheed Electra was a realistic choice. Going to a jet meant what? Neither the BAC-111 nor the DC-9 were certified to fly off gravel strips, plus neither were very good cargo airplanes. That left the new, yet unflown, Boeing 737 twinjet, although the 727 was also a possibility. (It was flying off gravel strips for Alaska Airlines.) The 737 had a big cabin for pax and freight (same as 707 and 727) and modestly long range for Caribbean charters. But, it also could not fly off gravel strips - at least initially - and, with its low, wing-mounted engines, appeared the least likely to be able to.

At the time, Boeing was Bottom-fishing for customers. Late to the short-range, twin-jet market, the BAC-111, DC-9, and Caravelle had already scooped all the larger customers- those with big order books and check books to match. Eastern, Delta, TWA and many local service airlines - like Southern, North Central, West Coast, Ozark had gone for the DC-9. American, Braniff, Mohawk had gone BAC-111. United was flying Caravelles, as were most European airlines.

As Boeing looked around for customers, there appeared to be a market niche of smaller airlines that needed cargo capable airplanes. A common theme was they all flew to the North, where gravel strips were the Norm. Also, they were all good for only onesies and twosies - i.e. small orders - but together, they might be a decent size. Airlines like Alaska, Wien, Northern Consolidated, Nordair, Eastern Provincial, Canadian Pacific, Pacific Western and Transair all fell in that bucket. When you're hungry and desperate, you'll try anything - so Boeing decided to fill the void by committing to an airplane certified to fly off unpaved runways. Then the orders from all those customers flowed in. But how was Boeing going to do this? Although they ultimately succeeded this could have ended very differently!

Frank Henley took the bait, and ordered 4 airplanes for Nordair. Transair, Pacific Western, Wien and NCA followed. Later, Canadian Pacific and Alaska joined the queue. Now, how was Boeing going to make this happen? Well, it took them a while - and longer than they first thought, but they did - and 737-200Cs with Cargo Doors and Floors and Gravel Kits remain the mainstay of northern flying more than 50 years later. Nordair's

initial

737s were configured to provide for the above route structure. They

were max high gross weight (for the time - 111,000 initially, later 114,000 lbs MTOW)

airplanes, with main deck cargo doors and gravel runway capable. But

it didn't take long for them to realize that they could perform many

of their missions with less robust airplanes, that needed less range,

no heavy-duty cargo capability, and could only operate from paved

runways. To accommodate that mission, they quickly leased three

737-200s from United Air Lines. They were passenger only non-gravel

airplanes with MTOW of 100,000 lbs. These airplanes filled the gap

Nordair was facing before their next new delivery from Boeing which

wasn't scheduled until May 1970. One other factor driving them in

this direction was the paving of several previously gravel runways in

the North. One runway that got paved was at Fort Chimo. Another was

at Churchill Falls, Labrador. Nordair 737-222 CF-NAI (leased United N9064U)

Churchill

Falls, Labrador (CZUM)

was

a private airport constructed to support the building of the huge

hydro-electric power plant on the Grand or Churchill River. The airport had a 5500 ft gravel runway that was paved in late 1969. There was an NDB beacon approach. The airport had several small buildings, including a small terminal and the airport, runway, and buildings were all owned and controlled by the power plant consortium, with some aviation functions turned over to the Canadian DOT. Nordair began serving the airport on March 31, 1969, with their gravel equipped 737s. My Logbook shows I last flew in there on Aug. 14, 1969, and the strip was then still gravel.

Final Approach and Take-off from Churchill Falls - 14 Aug 1969 The ramp at Churchill Falls The

second of the three UAL 737s (N9064U) was delivered new to Nordair in

Nordair markings from the Boeing factory on July 10, 1969. It

was placed on the Canadian Registry with a Tail Number CF-NAI. My

records show

APU (Auxiliary Power Unit) problems from the beginning, with the APU bleed valve cycling at

delivery with only 5:06 hrs TT flight time on the meter. It was a

troublesome airplane with numerous mechanical problems over the next

six months including APU problems on July 15, 16, 18, 19, 21, 22, 23,

29, and 31. Cockpit of CF-NAI

On Nov. 14, 1969, airplane CF-NAI flew a load of pax in there (Churchill Falls) in support of the power plant project - the strip having been just paved (NAI was non-gravel runway capable.) After turning around with an outbound load of pax, the airplane was unable to start engines because of APU problems. With no personnel or maintenance capability at the airport, Nordair Montreal was contacted with a request for assistance. The pilot described the problem as either APU surging or APU bleed valve inoperative or "something." This was the same problem that had been plaguing the airplane for the 4 months since delivery from Boeing, and had even occurred on the delivery flight. My log shows a continuing stream of "fixes", with virtually every possible component, on both the airplane, and the APU side, having been changed (most, multiple times.) Nordair - a small airline - had a small, but capable Engine Shop. The engine shop was responsible for Engine Build-Ups (EBU's) that converted bare engines into an installable powerplant (called QEC's - for Quick Engine Change) by installing the myriad accessory components (like hydraulic pumps, generators, etc, wiring, tubing, ducting), and all the associated brackets and clips. They also worked on cowling and APU's. It was staffed by two mechanics - Yvan Maurice and Bert Horne. Yvan was a small, wiry French-Canadian who was highly capable and knew his job inside and out. It was decided that Yvan and myself would proceed to Churchill Falls on 737 NAH with a big collection of tools and replacement parts to enable return of NAI to service. As in my rescue mission to Fort Chimo two weeks later, Nordair elected to send no other mechanics or supervisory maintenance personnel. Guess they figured I was the maintenance supervisor. More like a Player-Coach. The Fort Chimo rescue also involved a failed APU and a bunch of pax that were forced into a small building to survive the cold weather. You can read its story in the Link at the bottom of this page.. The flight to Churchill Falls was 1:48 and when we arrived it was dark, cold and "wet" - but not snowing. As with most all of the industrial site airports Nordair flew into, (powerplants, mines, etc), there were virtually no personnel who knew anything about airplanes and zero equipment on site. So, for starters, there was no easy way to get up to the APU - which is high in the tail. One fortunate thing was, we didn't swap airplanes, and so held NAH on the ramp instead of being left alone (like I was two weeks later, in Fort Chimo.) More about that in a bit.

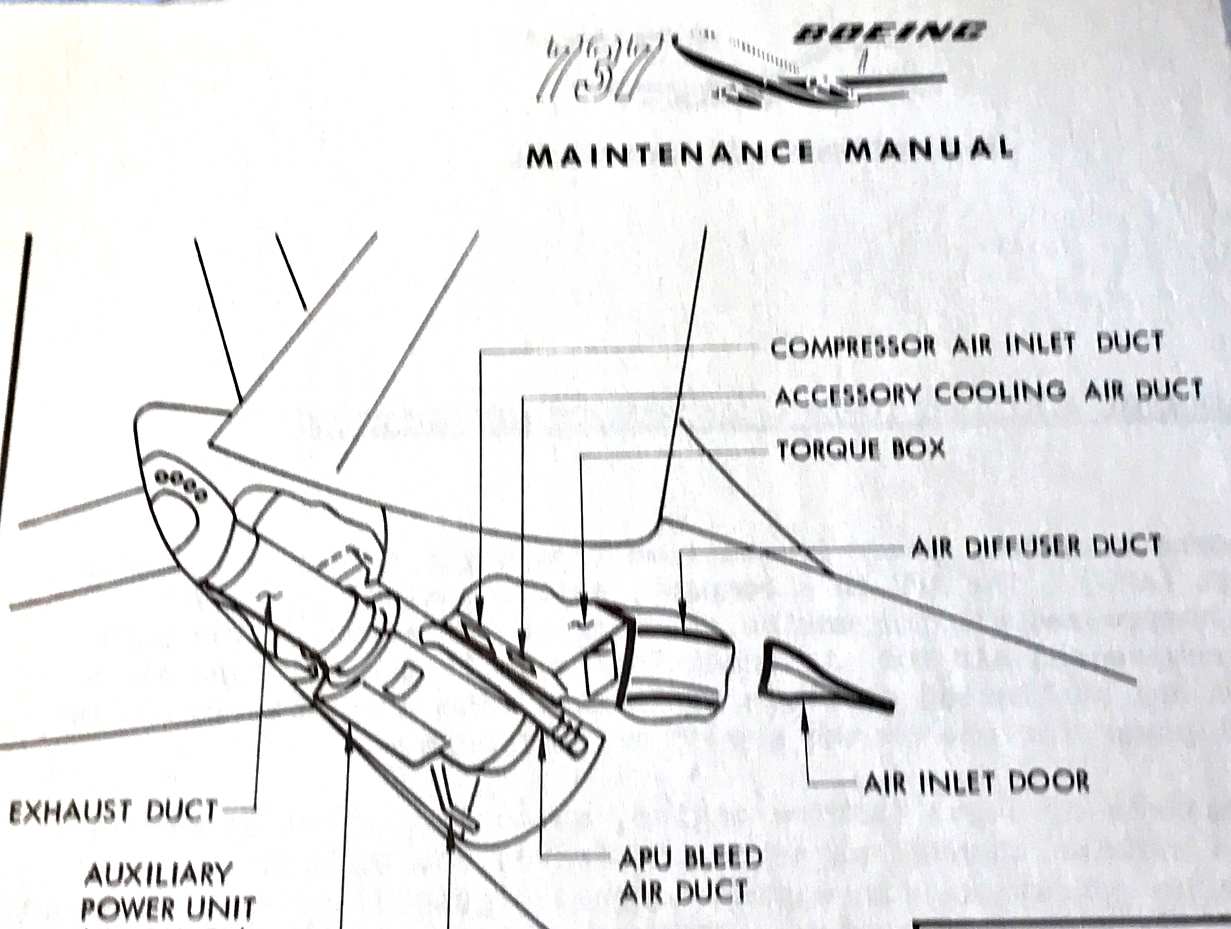

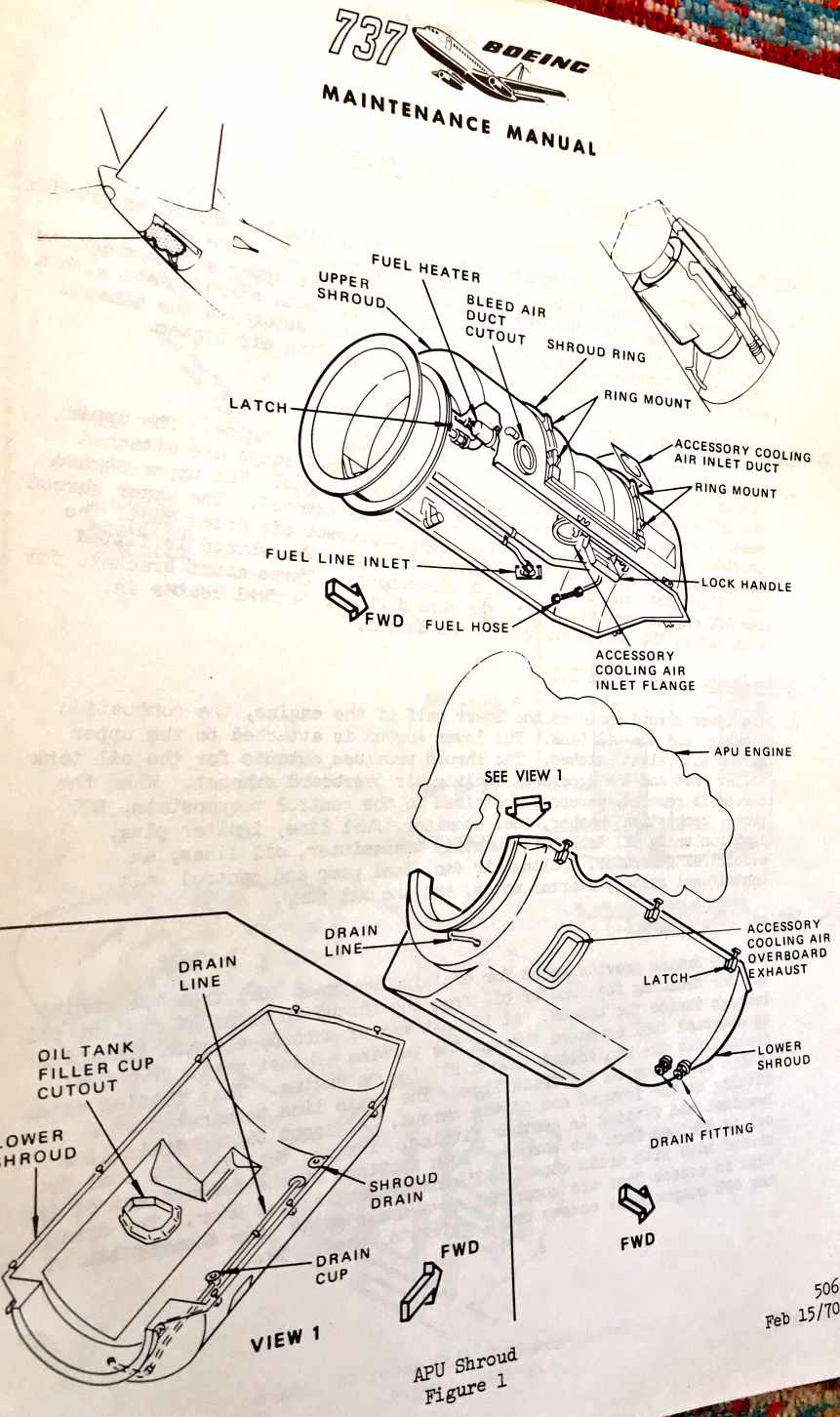

The APU is housed in a compartment in the tail. It is a small gas turbine engine (manufactured by AiResearch) that supplies electrical power and compressed air for air conditioning and engine starting. Although it is primarily intended to support the airplane's operations on the ground, it can also be run in-flight. To gain access, there is a large external door with hinges on one side and latches on the other. You release the latches, then open the door and keep it open with hold-open rods. If you want serious access to the APU itself and its components, you have to remove the lower shroud. The APU is encased, within its compartment, in a two-piece, upper and lower stainless steel shroud intended for fire protection.   To accomplish any work on the APU, you need access, and in a "normal" airline setting, you would use a stand with steps commonly called an Aerostand. Or some other sort of high lift truck. Churchill Falls had nothing. The only thing they had was a single forklift truck; so we had to stand on one of the forks in the cold, wet, dark. Forklift forks, especially their upper surface, are usually very shiny and slippery, because they are polished smooth by numerous insertions into pallets. I tried to locate some pallets that could be used as a makeshift platform, or even just boards, but there was nothing. Just the bare steel forks. With nothing to hang on to. An easy slip and fall to the ramp below was continually lurking. Whatever the conditions, it was just me and Yvan trying to hang on to each other as the forklift operator raised and lowered the forks and maneuvered the truck around at our direction. We dropped open and secured the APU cover, or cowl. then we removed the lower shroud. Doing this in the dark and cold while slip/sliding on the forks was an adventure. APUs are loud - ALL APUs - and NAH's APU running all the time 100 ft away made a racket. Besides my sanity, APUs probably cost me my hearing. My notes are fairly incomplete on our exact troubleshooting, but several things stand out. First thing we did was look down the tailpipe. Don't know exactly why - not totally worthless, as maybe we might see a bunch of turbine blades lying there. It's possible. But, it's part of the ritual - sort of like how people look under the hood of their cars when they break down. Not sure what they expect to see. But - in this case it was worthwhile. There are several temperature probes sticking up in the tailpipe, and we immediately saw the longest was broken off. A'ha! (we thought). This is going to be the easiest repair ever! And, we had one of those dudes with us. We changed that probe; also its harness and control box. Next the thermostat, and finally, the bleed valve itself. I noted the total time on the APU as 818 hours. As we replaced parts, at each stage, we tried to start the APU. The attempts were all unsuccessful. Eventually, we had replaced all the components we had brought with us. But -- guess what: we still had a broken airplane which was unable to start its engines.

Things looked a little bleak, at this point. We had one broken airplane. We had a shack full of passengers - maybe like 100. And we had a second airplane that we had flown out there, that was standing by. Just that part wasn't cheap. Do we load the pax on NAH and send them back to Montreal? Meaning what? Nordair would have to send yet another rescue airplane with yet more parts and more mechanics?

Well - all was not lost. We had one more Ace in the Hole. United Air Lines had developed a solution for this sort of predicament - a Buddy Hose. And Nordair had bought one. And we had it with us in the belly of NAH. The buddy hose comprised a long fabric hose - about 4 inches in diameter - very much like a fire hose in appearance. It had fittings at both ends that would connect to the External Air fittings on the airplane. What you did was park one airplane next to the other, and run the hose between the airplanes. Then the airplane with the good air (APU or engine) would pressurize the sick airplane so that it could get its engines started. We were in business!!! We re-positioned NAH to be close by NAI (had to do this carefully by taxiing, (no tug, no towbar) and not winding up in an inextricable position on the small ramp). We then removed the Buddy Hose from NAH and strung it over to NAI. With both ends of the hose connected to each airplane, we opened the APU bleed air valve on NAH. The hose should have filled up, stiffened up and straightened out with about 40 psi pressure. But nothing. Puzzled, I then ran over and jumped in the cockpit of NAI ready to check the air, and do a battery start of one of the engines. But wait! The Sky Gods. Remember them - those damn Sky Gods. Look up from an airplane ramp and you can see them snickering and laughing. There was no air pressure on NAI's air pressure gage. I couldn't believe it. No air. Damn! What could be the problem? Running

back and forth across the dark ramp and between airplanes, we shut

off NAH's air and then pulled the connecting fitting. All appeared

OK.

I got a flashlite and looked at the fitting and the receptacle.

There it was - the problem. Just above the receptacle was a small,

two-piece flapper - a check valve. Of course! You wanted air to go

IN the receptacle, but you didn't want it to go OUT. I stuck my

fingers up and could easily flip them out of the way. They were

spring-loaded closed and the duct air pressure would keep them

sealed. I sat on the dark wet ramp with Yvan and muttered to myself. How could UAL expect this contraption to ever work with that flapper valve sitting there. They must have never used this POS. Wonder how much Roger (Morawski) paid for this Piece of Crap? This could never work. How could we hold that flapper valve open??? Screwdriver? Vice-grips? I'll

give you a little Secret - right here and now - before the end of

this crazy story - which gets even crazier. The Buddy Hose is a

two-part unit. One part is the hose, and the second part is a small

little piece of pipe called a Block, with two notches. You insert it

in the Donor airplane's external air receptacle so that it holds the

flappers of the check valve Open. That's how you get air to the

second airplane. We didn't have, and

didn't

know about this check valve Block. And it was never found - even

back in Montreal. It was either lost when shipped to Nordair or

never included. And there was no Instruction Sheet with the gizmo.

Real Men don't need Instructions anyway. There's that Check Valve - just above the Ground Pneumatic Connector So - now we were stuck again. Two steps forward, one step back. Or was it the other way around? Two airplanes in Churchill Falls, Labrador, literally in the middle of nowhere, one is broken, two ace-hot "mechanics" and a box full of parts - all replaced, - dark, cold, wet, and the bad airplane is still bad, and our super-duper UAL Buddy Hose is NFG. What do we do now? Call Montreal and tell them to send a third airplane out here? With what? We're running out of time, running out of airplanes, running out of money, and running out of ideas. We had already run out of parts. All at the same time. Chester A. Riley (William Bendix) working at TV's Cunningham Aircraft, (for you Old-Timers) had a phrase for this: "What a revolting development this is!!!" "OK, OK", I told Yvan - "I've got an idea" (that never means good things are about to happen!) - "what do you think our chances are of slipping this hose (similar size, shape, composition and appearance to a fire hose) over one of the airplane's ducts? Do you think we could force it over? And if we did, do you think we could somehow clamp it enough so it wouldn't blow off - I mean it's got 40 lbs pressure trying to blow it off.?" Hot, hot air too - lemme tell you. Lemme also tell you, this is a REALLY hair-brained idea. Even for me - King of the Hair-Brained Ideas. (Did I ever tell you the one about trying to block the door of a Cessna 150 open with my foot over the Oregon coastal mountains so I could take a pee over the side? No? Well, I did, and that didn't work either....)

We

discussed this for a while, including possible tap-in locations.

Finally, we opened the cowling on NAH. Why have one screwed-up

airplane when you can have two? I figured the place to do it was

just above the Nbr 1 engine bleed valve. We could remove the valve

and then slip the hose over the bottom end of the open duct.  The

problem though, was the duct had a flange. The flange on the duct

mated with the flange on the bleed valve and they

were

secured when you

attached a Marman

(V-band)

clamp

securing the two flanges together. We'd

have to somehow slip that hose over the flange and then secure it

with the Marman clamp behind the flange.

As Benjamin's father said in the movie The Graduate, "Bob, this idea

seems kind of 'half-baked' ".  Marman clamp Marman clampLike

two down-and-out bums

sitting on the ground in the dark

after the bars had closed,

we decided to pull the bleed valve to "evaluate further". Once off, we

brought over the end of the Buddy Hose and eye-balled the possible

connection. The next step would mean cutting off

the External Air connector from the hose itself - potentially

ruining

the hose. Wonder what that hose cost? Well, in for a Penny, in for

a Pound. We pulled out a knife and cut the end off the hose. Now we manhandled the cut end towards the open bleed air duct. Everything was frozen - the hose was frozen, the duct was frozen, we were frozen. It became immediately obvious how hair-brained this scheme was. We'd never get that hose end over that duct flange. Well, again, we were past V1, and destined to either take-off or crash and burn. We slit the hose for about a foot along its axis to help get it started over the flange. Then, by brute force and endless pushing and shoving, and quite a bit of swearing (a good deal in French), we got a decent length over the flange. Yvan must have figured "is this the kind of guy Boeing sends out here???" Next we attached the Marman clamp around the hose behind the duct flange. We pulled and tugged on it and it seemed attached pretty good. We sat back down on the wet dark ramp and admired our handiwork. Bet this isn't in FAR 43 - Acceptable Practices! So,

if this worked, we'd be in business. If it didn't work - meaning

likely the hose would blow off the end of the duct,

there'd be a god-awful screaming

noise

and blast as the hot

bleed

air from NAH's APU came roaring out the wide open pipe. Maybe wipe

out NAH's APU in the bargain. Who knows? Then, we'd have to make the dreaded

call back to Montreal. And Nordair could call Boeing and say "your Rep just ruined two airplanes and an APU." We decided our chances were better than 50/50, so before we went any further, we had to button up NAI's APU compartment. We didn't dare try that with an engine running. More time on the fork lift slippery forks as we reinstalled the lower shroud and then closed and latched the access door. If our scheme (notice how it's now "our" scheme) - didn't work, we'd have to maybe open it all up again. But that was thinking too far ahead.

We went up into NAH's cockpit. I seated Yvan in the pilot's seat with the window open. I showed him what to do if the hose blew off - he wasn't really familiar with the cockpit controls. "Watch the hose from Nbr 1 engine", I told him. "If it blows off, close the APU bleed air valve using this switch - Right Away!" Meanwhile, I would open NAH's APU bleed valve --- the hose should stiffen from the 40 pounds of air pressure. If it stayed stiff and seemed OK for a few minutes, I would run over to NAI and do a quick battery start of her Nbr 2 engine. Once it started, I would signal Yvan from the co-pilot's window to close NAH's APU bleed valve. Next, he would pull the Buddy Hose from NAI's receptacle and latch the access door. I warned him sternly "For Christ's sake, Nbr 2 will be running - don't run in front or behind the engine - only approach from the nose along the fuselage!!!" Then I would run like hell to get NAI's pilots, get them in the cockpit, while I worked with the Stewardesses to get the passengers loaded via the L-1 door's forward airstairs. (NAI only had a Forward airstairs, and NAH only had an Aft airstairs - a lot of running back and forth down the aisle in NAH.) I wound up being the Gate Agent, Marshaling Mechanic, Dispatcher and everyone else that normally dispatches an airline flight - all rolled up in one. The ramp was slick, dark, black and dangerous; the noise from NAH's operating APU and NAI's operating Nbr 2 engine would be deafening. With everybody on-board, I'd brief NAI's pilots on doing the cross-bleed start of Nbr 1, then come back to NAH to help put it back together again.

And,

by

God, that's what happened. The clamp held the hose, and we pressurized

NAI's pneumatic system from NAH's APU - over 100 ft away! The

Ultimate Jump Start. I actually was able to do a

Battery start of NAI's Nbr 2 with air from NAH's APU through the

Buddy Hose. Tickle Me, Elmo. Next, I got the pilots, got the

stews, got the pax - all per plan; Yvan pulled

the Buddy Hose. NAI got all their pax on-board, closed the door,

started up Nbr 1 and departed for Montreal.  Cabin of 737 CF-NAI

Me

and Yvan then pulled the hose off NAH's Nbr 1 engine duct, stowed the duct

(with the now cut off fitting), reinstalled the bleed valve, closed

up the engine, loaded our tools and parts; I got my pal Red Martindale

- NAH's pilot (with F/O Peter Knox-Leet). We then started up,

took-off and flew back to Montreal (2:33).  Myself and Capt. Red Martindale on a happier day (in Nanisivik on Baffin Island). NAI's total delay was 7 hours - long for the pax jammed in a small building, but not bad at all from my knothole! Notify, analyze, load up, fly out, run around a lot, shotgun a fix, shoot a lot of blanks, run out of ideas, come up with new ones, accomplish and launch. We teetered on the edge of a really bad washout, but made it all happen. Just another day in the life of a Boeing Rep. My boss, Andy Jones, later told me he sent me to Nordair especially because they were asking for a "hands-on" guy, not an office-sitter. So, despite his "knock-it-off" letters, he knew what was going on. For the lawyers sake, he'd just never admit it. We

never did find that check valve block; I'm presuming Nordair ordered

one from UAL. And fixed the Buddy-Hose. Also, NAI's APU problem (this time) was traced to a bad

3-Speed Switch, a notoriously bad unit on the APU. Why we didn't fly

out there with one remains another mystery. CF-NAI

(N9064U) was returned to United in San Francisco on May 9, 1970.

The flight was a Revenue flight with a full load of passengers, and I

was on-board. We made a fuel stop in Salt Lake City. On

arrival in SLC, the APU failed (yet again.) The handling agency in

SLC had no ground air start capability, so we had to leave Nbr 1 engine

running while I refueled the airplane - a very bad practice in my book

(and one I am reluctant to admit.) We then made a cross-bleed

start of Nbr 2 (as we had in Churchill Falls six months earlier, and as

recounted in this story) and then flew her last leg with Nordair, from

SLC back into SFO. She arrived back at UAL with the APU

inop. The APU had failed during her delivery flight from Boeing on

July 10, 1969, had failed dramatically in Churchill Falls, and

fittingly, had failed again during her last flight 10 months later -

with assorted failures in the interim. At least she had been

consistent; my records show the APU had been changed six times during her stay with Nordair. United sold her six years later. Maybe they decided she was a "Monday airplane?" She eventually wound up flying with a total of 7 airlines before being retired and stored in Santiago, Chile in March 2001..... a lemon from Day One at the factory in my book.

Only two weeks later, I had another exciting adventure when airplane NAB got stuck in Fort Chimo with another load of passengers and another APU that quit. Rescuing stranded 737s with crapped-out APU's was becoming a habit - and not a happy one. The stories could fill the pages of a book...... |

|

|

Copyright 2021 Robert Bogash.

All Rights Reserved

|